Spin Coaters

Industry-leading precision

With spin speed resolutions and repeatability within 0.2 rpm, Brewer Science® Cee® spin coaters provide all the necessary precision for critical processes.

Broad chemical compatibility

Choose between Teflon®, stainless steel, or polyethylene spin bowl construction for maximum material compatibility.

Exceptional uptime and reliability

All Brewer Science® Cee® spin coaters feature an indirect drive system, which protects the spin motor from contact with process chemicals and solvents. Isolating the spin motor from the process environment greatly increases tool reliability and uptime.

Product Options

With numerous configuration options and a huge variety of substrate-specific spin chucks to choose from, Brewer Science® Cee® spin coaters can handle almost any application imaginable. Compare product specifications below to see which configuration is right for you, or contact us to request more information.

Cee® 200X

Cee® 300X

Substrate Sizes

Up to 200 mm round or 7″ × 7″ square

Up to 450 mm round or 14″ × 14″ square

PRECISION

Maximum Spin Speed

12,000 rpm

6,000 rpm

4,000 rpm and 3,000 rpm configurations available for additional acceleration capabilities

Spin Speed Resolution

Within 0.2 rpm

Within 0.2 rpm

Spin Speed Repeatability

Within 0.2 rpm

Within 0.2 rpm

Spin Speed Acceleration

Up to 23,000 rpm/s with 200-mm substrate

Up to 23,000 rpm/s with 300-mm substrate

Up to 3,000 rpm/s with 350 mm × 6 mm round recessed chuck

Up to 30,000 rpm/s unloaded

Up to 400 rpm/s with 14″ × 14″ × 11 mm photomask recessed chuck

Up to 30,000 rpm/s unloaded

CONTROL

Control Interface

Onboard Windows®-based PC with 7″ touch screen display

Connectivity

USB and ethernet ports for uploading/downloading process parameters

Third-Party Integration

System capable of controlling third-party host software for high-end IDI/Cybor/Mykrolis positive displacement pumps

Automated Dispense Control

Simultaneously trigger up to 16 automated dispense nozzles

Simultaneously trigger up to 16 automated dispense nozzles

Dispense or Component Outputs

16

16

Spin Control

Bidirectional speed control (oscillating chuck)

In-process dynamic speed/acceleration control

PROGRAMMABILITY

Onboard Storage

Up to 250,000 process recipe programs with a virtually unlimited number of program steps per recipe

Step Time

0.1 to 9,999.9 seconds with a resolution of 0.1 second

Security

Password protection available at no charge

DESIGN

Spin Bowl Design

Polyethylene spin bowl for optimal material compatibility

Integrated bowl ring to eliminate material migration

Drain and exhaust ports located in bottom of bowl

Stainless steel spin bowl

Drain and exhaust ports located in bottom of bowl

Lid Design

Closed- and open-lid designs available

Spin Environment

Optional nitrogen purge available for an inert spin environment

Reliability Features

Indirect drive system protects spin motor from contact with process chemicals and solvents

Vacuum and lid interlock with mechanical lock to prevent accidental process disruption (only 300X)

Dimensions

13.25″ W × 19″ D × 12″ H

(33.65 cm W × 48.26 cm D × 30.48 cm H)

Machine weight: 40 lb (18.14 kg)

Shipping weight: 100 lb (45.36 kg)

27.75″ W × 34.75″ D × 20.25″ H (70.5 cm W × 88.3 cm D × 51.5 cm H)

Machine weight: 115 lb (52.2 kg)

Shipping weight: 250 lb (113.4 kg)

UTILITIES

Voltage Ranges

100–125, 208–240 VAC 50/60 Hz

208–240 VAC 50/60 Hz

Power Requirements

655 watts

6.0 amps

1350 watts

7.0 amps

Drain Port

0.75″ OD

1″ OD

Exhaust Port

1″ OD

1.5″ OD

Vacuum

20–25 in Hg

20–25 in Hg

Exhaust

20–50 cfm at 0.2″ water column

20–50 cfm at 0.2″ water column

Nitrogen or CDA

(automated dispense)

70 psi

70 psi

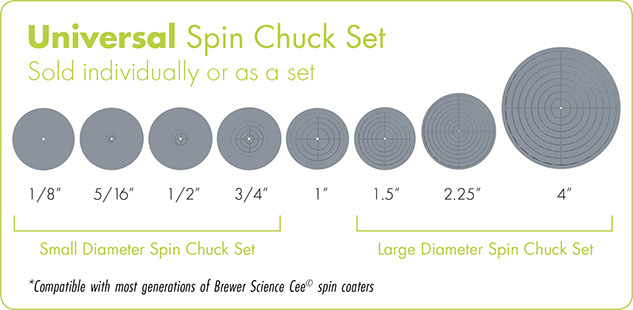

Universal Spin Chuck Sets

The Brewer Science universal spin chuck base offers the unique ability to seamlessly switch among chuck sizes ranging from 1/8" to 4" in diameter.

Benefits

● Universal spin chuck base that fits interchangeable chuck sizes from 1/8” to 4”

● Reduced cost for the capability of handling multiple substrate dimensions

● Faster switching between substrates of different sizes

● No hardware required for installation

● Resistance to a wide variety of chemistries

● Compatibility with most generations of Brewer Science Cee© spin coaters (call to check

compatibility)

● For sets, a storage case for chuck sizes not in use

Brewer Science is offering 4 different options...

The Summit-Tech Company is an ISO:9001-2015 certified company. Copyright ©1996-2016 Summit-Tech Company® All rights reserved.