Wafer-Scale Growth of Sb2Te3 Films via Low-Temperature ALD

Accessories

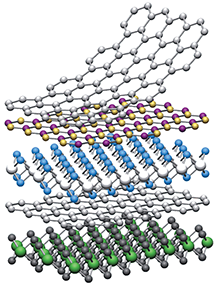

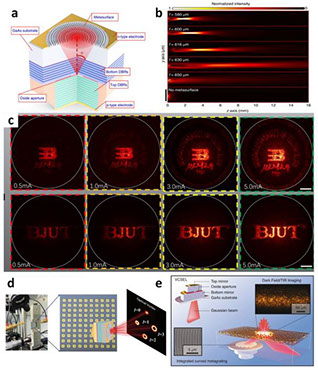

In this work, we demonstrate the performance of a silicon-compatible high-performance self-powered photodetector.A wide detection range from visible (405 nm) to near-infrared (1550 nm) light was enabled by the vertical p-n heterojunction between the p-type antimony telluride (Sb2Te3) thin film and the n-type silicon (Si) substrates. A Sb2Te3 film with a good crystal quality, low density of extended defects, proper stoichiometry, p-type nature, and excellent uniformity across a 4-inch wafer was achieved by atomic layer deposition at 80 °C using (Et3Si)2Te and SbCl3 as precursors. The processed photodetectors have a low dark current (~20 pA), a high responsivity of (~4.3 Ampere per Watt at 405 nm and ~150 milli-Ampere per Watt at ~1550 nm), a peak detectivity of ~1.65*10^14 Jones, and a quick rise time of ~98 us under zero bias voltage. Density functional theory calculations reveal a narrow, near-direct, type-II bandgap at the heterointerface that supports a strong built-in electric field leading to efficient separation of the photogenerated carriers. The devices have long-term air stability and efficient switching behavior even at elevated temperatures. These high-performance self-powered p-Sb2Te3/n-Si heterojunction photodetectors have immense potential to become reliable technological building blocks for a plethora of innovative applications in next-generation optoelectronics, silicon-photonics, chip-level sensing, and detection.

New technique can measure electronic properties of 2D materials

New perovskite solar cell

Ferroelectric materials can generate power from ‘hot’ electrons

Hot attraction of gold

Gold had long been considered a non-magnetic metal. But researchers .....

Self-healing Material

The experimental electronics material works in high humidity and even after being cut in half - once it heals itself.

Storage Memory Breakthrough

Technology can speed up machine learning and access to the Internet .......

Superalloy industry

Master Alloys e.g. ferro niobium (FeNb), nickel niobium (NiNb), nickel tantalum (NiTa) or nickel zirconium (NiZr) are used by the superalloy industry as alloying elements in the manufacture of superalloys.

The Master Alloys improve the mechanical properties (corrosion and heat resistance) of the superalloy.

Superalloys that provide these properties will used in following industries:

Aviation industry (e.g. engines, airplane parts)

Power plants (e.g. turbines)

Chemical plant construction

Ship-building (e.g. submarines)

Off-shore technology (e.g. pipelines)

The Summit-Tech Company is an ISO:9001-2015 certified company. Copyright ©1996-2016 Summit-Tech Company® All rights reserved.