Si Wafer

SOI Wafer

Sapphire Wafer

III-V Wafer

GeSn thin film Wafer

Glass Substrate

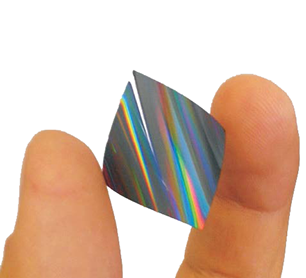

Macroporous

Other Substrate

Porous silicon was accidentally discovered by Uhlir at Bell Laboratories in the mid 1950s. He was trying to develop a means to electrochemically machine silicon wafers for use in microelectronic circuits. He found that under the appropriate conditions of applied current and solution composition, the silicon did not dissolve uniformly but instead fine holes were produced, which propagated primarily in the <100> direction in the wafer. Since this did not provide the smooth polish desired, these curious results were reported in a Bell labs technical note and the material was pretty much ignored. In the 1970s and 1980s a moderate level of interest arose because the high surface area of porous Si was found to be useful as a model of the crystalline Si surface in spectroscopic studies, as a precursor to generate thick oxide layers on Si, and as a dielectric layer in capacitance-based chemical sensors. Then, in the late 1980s, Leigh Canham at the Defense Research Agency in England reasoned that the diaphanous Si filaments generated when the pores become large and numerous enough to overlap might display quantum confinement effects. This intuition turned out to be correct, and the electrochemically etched material was reported to fluoresce with a bright red-orange color. As expected from the quantum confinement relationship, this color is at an energy that is significantly larger than the bandgap energy for bulk Si, which occurs in the infrared region of the spectrum.

With the discovery of efficient visible light emission from porous Si came an explosion of work focused on creating Si-based optoelectronic switches, displays, and lasers. Problems with the material’s chemical and mechanical stability and its disappointingly low electroluminescence efficiency led to a waning of interest by the mid 1990s. In the same time period, the unique features of the material- its large surface area within a small volume, its controllable pore sizes, its convenient surface chemistry, and its compatibility with conventional silicon microfabrication technologies-inspired research into applications far outside of optoelectronics. Of particular relevance to our research are the biomedical and sensor properties of the material.

Applications of porous silicon

Application area

Optoelectronics

Micro-optics

Energy conversion

Environmental monitoring

Role of porous silicon

LED

Waveguide

Field emitter

Optical memory

Fabry-Pérot Filters

Photonic bandgap structures

All optical switching

Antireflection coatings Photo-electrochemical cells

Gas sensing

Efficient electroluminescence

Key property

Tunability of refractive index

Hot carrier emission

Non-linear properties

Refractive index modulation Regular macropore array Highly non-linear properties

Low refractive index

Photocorrosion cells

Ambient sensitive properties

Microelectronics

Micro-capacitor

Insulator layer

Low-k material

High specific surface area

High resistance

Electrical properties

Wafer technology

Buffer layer in heteroepitaxy

Variable lattice parameter

SOI wafers

High etching selectivity

Micromachining

Thick sacrificial layer

Highly controllable etching

Biotechnology

Tissue bonding

Biosensor

Tunable cht emical reactivity Enzyme immobilization

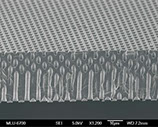

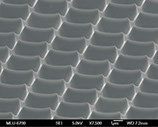

MakroPor

Interpore distance

1,5 µm

4,2 µm

12 µm

Pore diameter

0,8 - 1 µm

2 - 2.5 µm

5 - 6µm

Pore length

200 µm

500 µm

500 µm

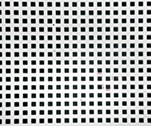

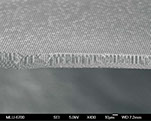

SmartPor

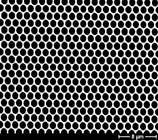

FlexiPor

Interpore distance

65 nm

125 nm

480 nm

Interpore distance

20 ± 8 nmt

100 ±15 nm

200 ±25 nm

Pore diameter

25 nm

40 nm

180 nm

Pore diameter

160 ± 10 nm

200 ± 15 nm

220 ± 25 nm

Pore length

50 µm or 100 µm

50 µm or 100 µm

50 µm or 100 µm

Pore length

50 µm or 100 µm

50 µm or 100 µm

50 µm or 100 µm

The Summit-Tech Company is an ISO:9001-2015 certified company. Copyright ©1996-2016 Summit-Tech Company® All rights reserved.